Take your production to the next level

| Conversations about AI, data, and digital tools are important, but the real value comes when insights are turned into action on the shopfloor. |

| Taking Part in the AI Conversation at SUBCON |

| Earlier this month, Virtual Manufacturing UK had the opportunity to take part in a thought-provoking panel session at SUBCON, exploring the practical applications of AI in manufacturing. Representing our team on stage, our Managing Director contributed to a lively discussion on how manufacturers can approach AI with purpose and avoid common pitfalls.

The key message? Start two steps before AI. Before diving into AI solutions, manufacturers need to lay the groundwork: 1. People, process, and expertise 2. Data quality and structure As we continue supporting manufacturers in digital transformation, we’re proud to contribute to conversations like this bridging strategy, data, and technology for real-world impact. |

| Support throughout the process |

| We guide companies through every step of the industrialization process – from feasibility study to implementation.

In the feasibility study, we map the current situation through an “As Is” analysis and define a future scenario “To Be”. We identify challenges and opportunities and create a clear plan for how the change can be implemented. In detailed planning, we concretize the chosen future scenario by developing a final specification and basis for procurement. We ensure that all technical, economic and organizational aspects are well thought out for a smooth transition to the next phase. During implementation, we support installation, operator training and acceptance tests – both virtually and physically. We ensure that operations start according to plan and help with tuning and adjustments to optimize the production flow. Through our structured process, we minimize risks, shorten lead times and create a safe and cost-effective path from prototype to full-scale production. |

Methods we use

Virtual Twin

Using 3D scanning, we create an exact digital replica of the facility, enabling simulation, optimization and planning in real time. Through a web-based application, users have easy access to panoramic images, point clouds and interactive features to improve maintenance, layout planning and production flows.

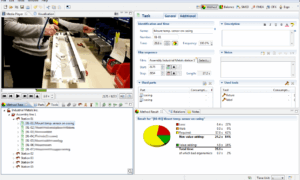

AVIX

AVIX provides detailed insight into both individual steps and entire production lines, enabling better capacity planning, improvement work and work instructions. With a clear, visual presentation of data, it becomes easier to make informed decisions for more efficient production.

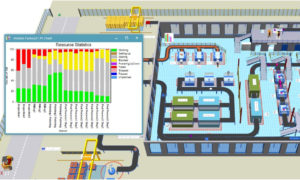

DES – Flow Simulation

With flow simulation, we can analyze and visualize production and logistics facilities without disrupting ongoing operations. We identify capacity constraints, bottlenecks and optimization opportunities to ensure better resource utilization and shorter lead times.