CERATIZIT’s durable side milling cutter system keeps cuts smooth

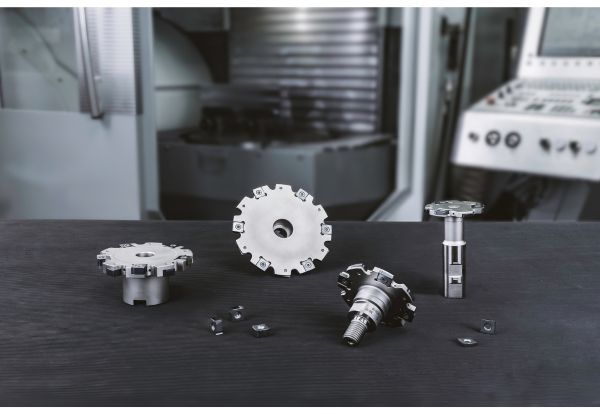

Unstable machining processes can be a tough nut to crack for machinists when cutting grooves in steel, stainless steel, cast materials or aluminum. With the soft-cutting side milling cutters in the MaxiMill – Slot-SNHX system, even the most-difficult challenges are a walk in the park. And thanks to its wide range of carriers and indexable inserts, it covers a wide range of cutting widths (6 to 16 mm) and diameters (50 to 200 mm), while ensuring cost-optimized machining.

Characterized by versatility and precision, the MaxiMill – Slot-SNHX features trouble-free contours on the face side and sufficient axial freedom of movement that ensure smooth machining — even in hard-to-reach areas. Thanks to precision-ground indexable inserts, machinists can expect a flat groove base that ensures perfect surfaces from the very first cut. The system is also equipped with an internal coolant supply up to a diameter of 200 mm, which minimizes chip jamming and further boosts efficiency. “We strongly believe that we can combine soft cuts with stable side milling cutters. The MaxiMill – Slot-SNHX delivers excellent cutting performance on steel, cast iron and aluminum, while gracefully navigating every pesky, in-the-way contour,” says Robert Frei, Product Manager at CERATIZIT.

Universal connections? Yes please!

The MaxiMill – Slot-SNHX is available in three carrier variants to offer the most universal connection on the market. These slip-on milling cutters offer diameter ranges from 80mm to 200mm, each of which include internal coolant supply, and cutting widths (CW) in 6mm, 8mm, 10mm, 12mm, 14mm and 16mm. The screw-in milling cutter provides also provides an internal coolant supply on diameters of 50mm, 63mm and 80mm and cutting widths of 6mm and 8mm. Rounding out the offer is the milling cutter with cylindrical shank and internal coolant supply is available to CERATIZIT customers in diameters of 50mm, 63mm, 80mm and 100mm as well as cutting widths (CW) of 6mm and 8mm.

The indexable inserts in the MaxiMill – Slot-SNHX are ground with high precision and suitable for P, M and K applications. They will be available upon market launch with a corner radius of 0.8 mm. The indexable insert has a 3° axial mounting position in the milling cutter, which ensures good clearance and even makes rear-side machining possible. To ensure that no operating errors can occur when fitting the corresponding indexable inserts, the carriers are labeled accordingly on the insert seats and there are clear markings for right and left indexable inserts.

Superior performance and tool life

The MaxiMill – Slot-SNHX tools also compare favorably with the competition—as determined by tests in the back machining of ductile cast iron. In these tests, the competitor product machined 200 parts with a carrier tool with a diameter of 160 mm and six effective cutting edges (in-feed depth: 3 mm, insert width: 42 mm), while the CERATIZIT side milling cutter took it a step further. “Our solution, which uses 5 active teeth, increases the tool life to a remarkable 600 parts. In addition, machinists benefit from better handling due to the large insert clamping screw and minimized set-up effort with fewer indexable inserts than the competition,” adds Robert Frei.

Effectively minimize vibrations

If vibrations persist, special measures have to be taken. The combination of MaxiMill – Slot-SNHX tools and a vibration-damped, cross-slot milling arbor provides an enormous advantage. This special damping mechanism in the body of the vibration-damped cross slot arbor efficiently minimizes vibrations throughout the process. “Especially with long overhangs, this feature results in significantly better surface finishes and higher productivity, as machinists can increase either the cutting speed or the feed rate without giving it a second thought,” says Frei.